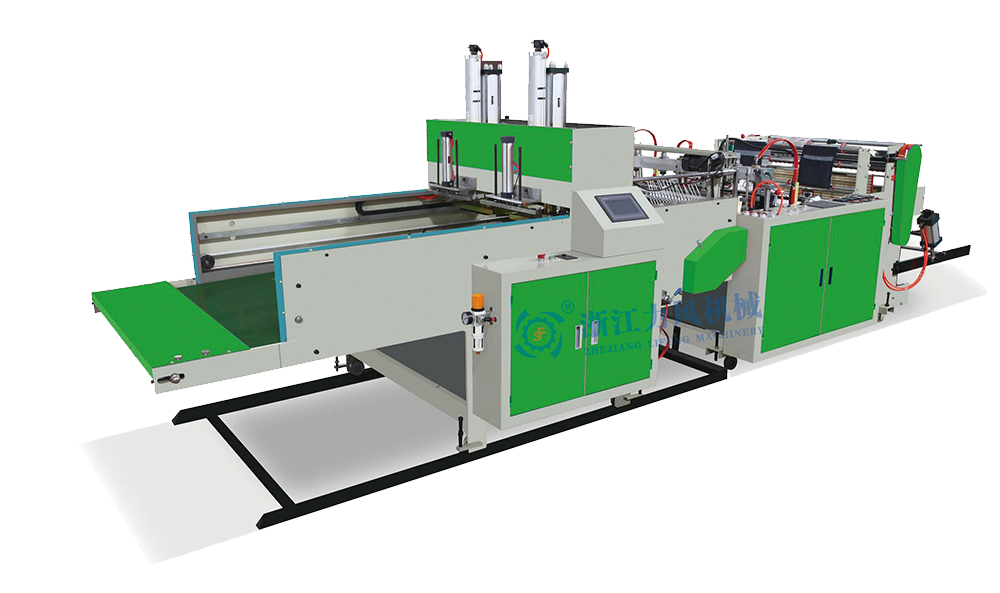

Performance and allocations:

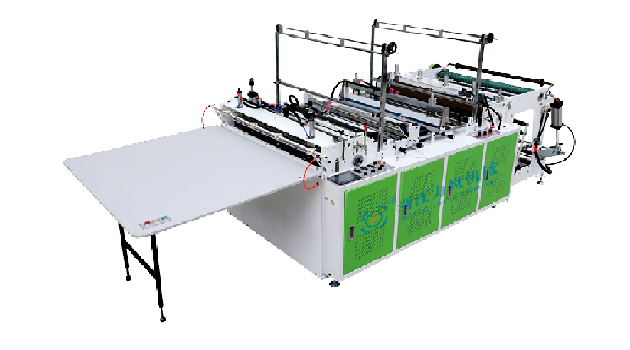

1.Especially designed for ho sealing and cutting of T-shirt bag.It can be punched automatically in two production line which will increase the production and save the worker

2.Photocell for accurate registration of film printing points if the photocell can`t catch printing point,The machine will stop automatically

3.Invertor control speed,easy operation,reduce electric consumption

4.Automatic stopping when run out of film

5.Strong sealing and output bags being tear up neatly

6.Punching machine used air and liquid pressurized cylinder,so the noise is low and the gas consumption is little.

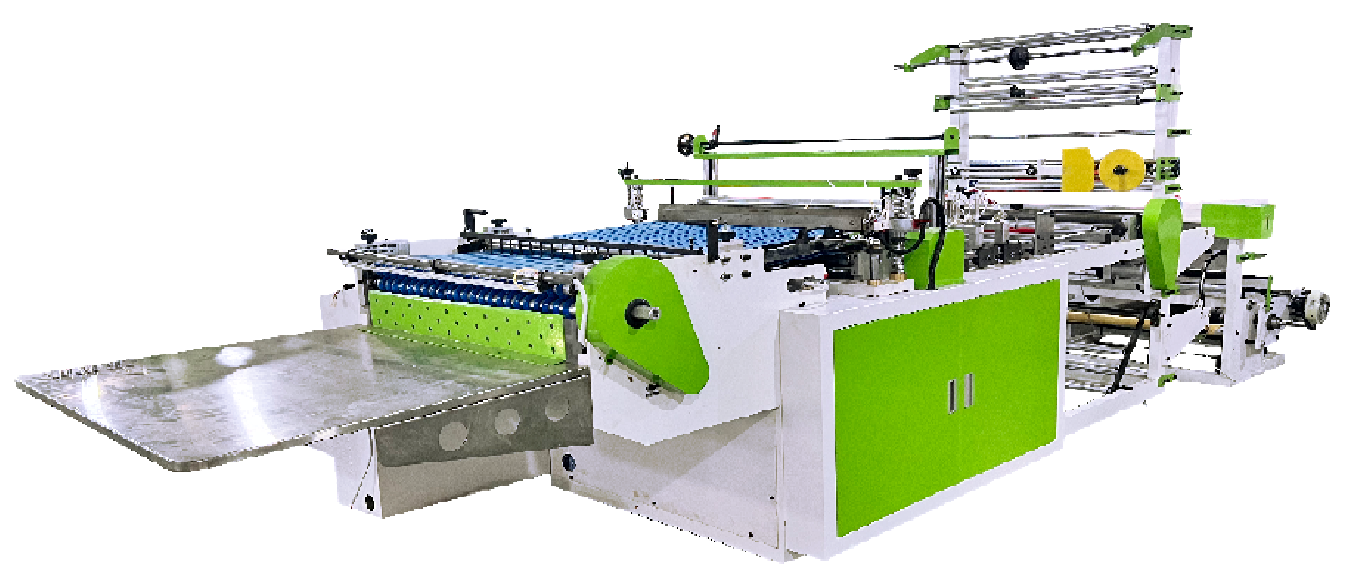

|

Model |

TC 470*2 |

|---|---|

|

Max Bag Width |

150-430MM |

|

Max Bag Length |

650MM We can also customize the punching machine length according to the length of the customer's bag |

|

Max Feeding Diameter |

470mm |

|

Producing Speed |

100-230pcs/min/channel 200-460pcs/min/2channels |

|

Film Thickness |

0.01-0.08mm single layers Total thickness 320 microns OK |

- Loading by pneumatic

- Shutdown for material breakage

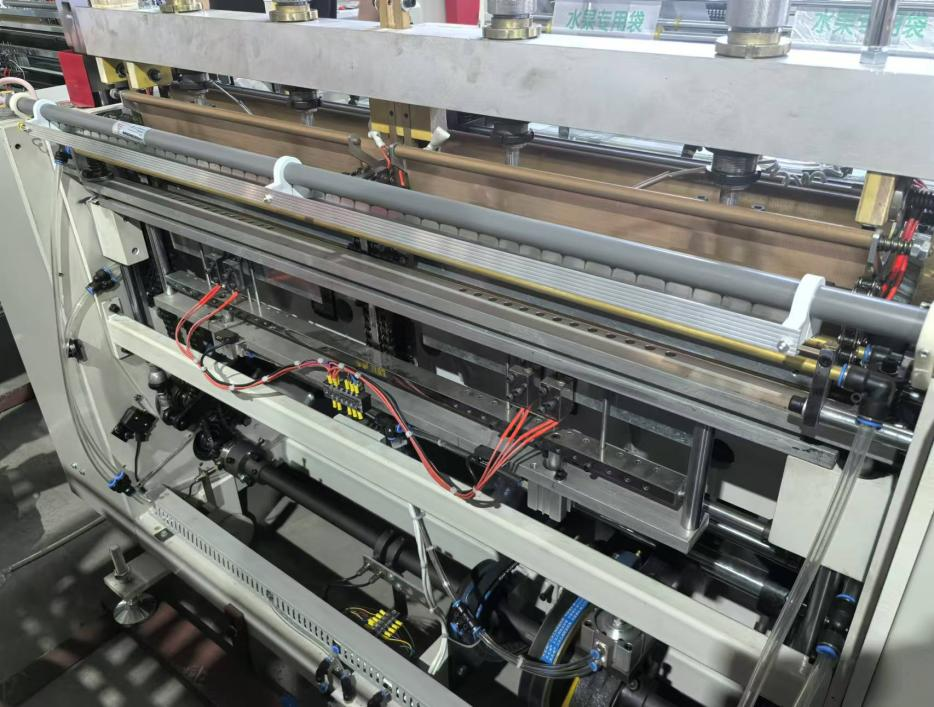

- High speed swing arm

- High speed swing arm

- High quality copper knife

- Punching Gripper